EPDM (Ethylene Propylene Diene Monomer) rubber seals and gaskets are widely used in various industries in the USA for their excellent properties and versatility

EPDM (Ethylene Propylene Diene Monomer) rubber seals and gaskets are widely used in various industries in the USA for their excellent properties and versatility. Here is a general description of EPDM rubber seals and gaskets:

-

Material Composition:

- EPDM is a synthetic rubber compound known for its resistance to weathering, ozone, UV exposure, and aging.

- It is composed of ethylene, propylene, and a diene monomer, which gives it its unique combination of properties.

-

Temperature Resistance:

- EPDM rubber exhibits excellent heat resistance, making it suitable for a wide range of temperatures, from -40°C to 120°C (-40°F to 248°F).

-

Weatherability:

- EPDM is highly resistant to weathering and ozone exposure, making it ideal for outdoor applications. It can withstand harsh environmental conditions without significant degradation.

-

Chemical Resistance:

- EPDM is known for its resistance to a variety of chemicals, including acids, alkalis, and polar substances. This makes it suitable for applications where exposure to different chemicals is a concern.

-

Water Resistance:

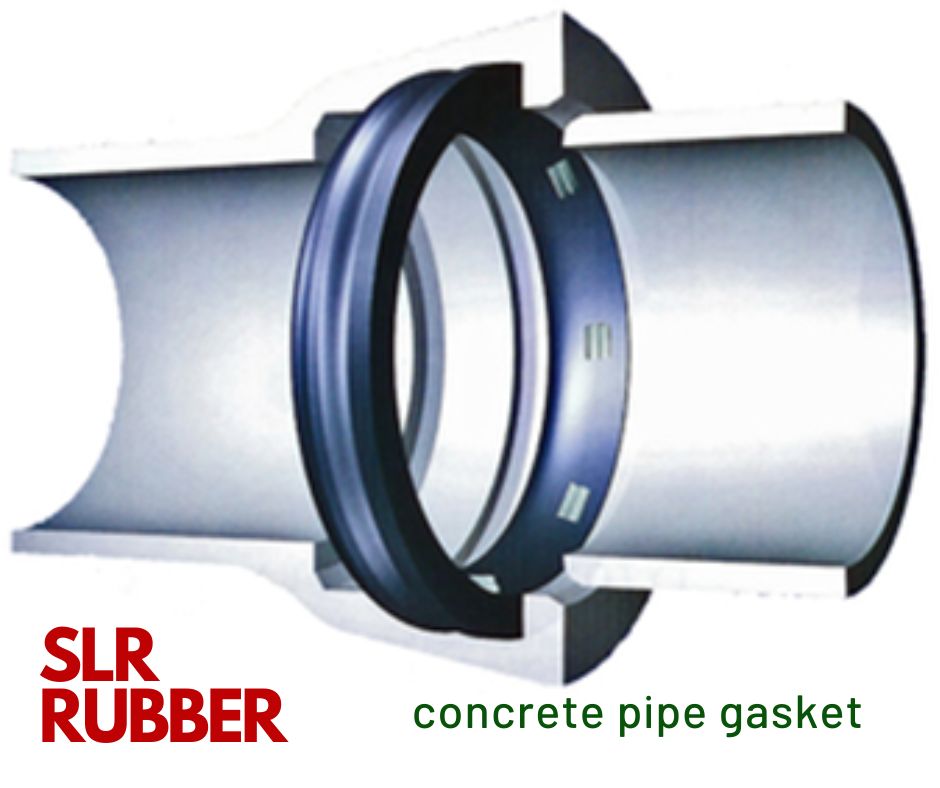

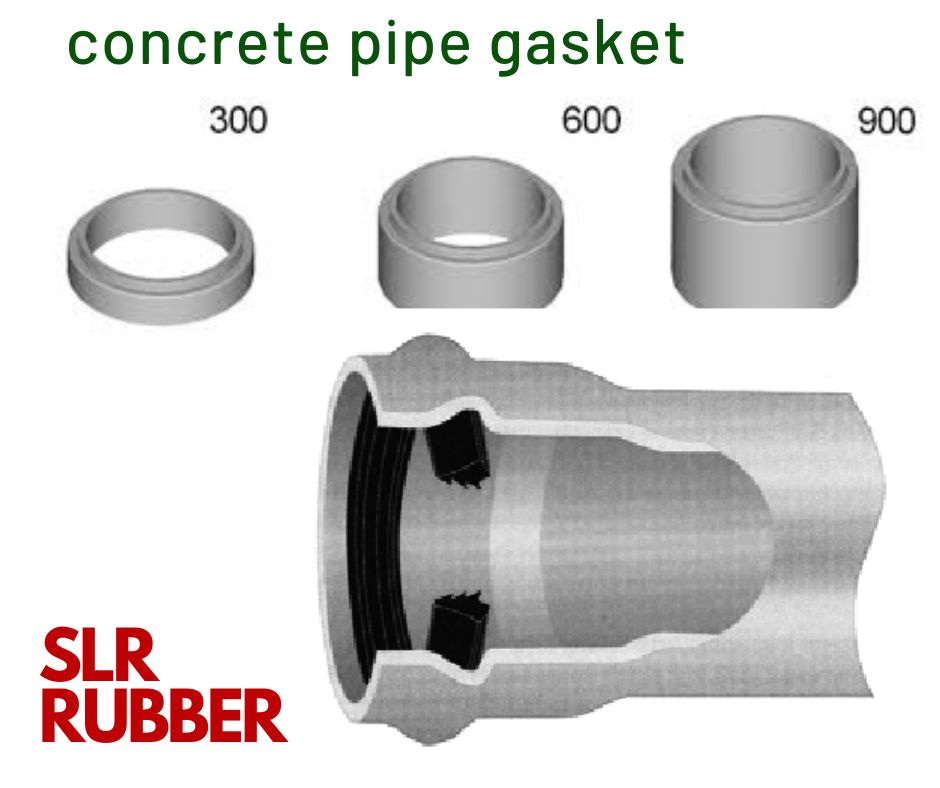

- EPDM rubber has good water resistance and is often used in applications where a watertight seal is required. It is commonly used in roofing systems, gaskets, and seals for plumbing applications.

-

UV Resistance:

- The material has excellent UV resistance, which is crucial for outdoor applications where prolonged exposure to sunlight can cause degradation in some materials.

-

Flexibility and Elasticity:

- EPDM rubber is known for its flexibility and elasticity, allowing it to conform to irregular shapes and provide effective sealing.

-

Electrical Insulation:

- EPDM rubber has good electrical insulating properties, making it suitable for various electrical applications.

-

Applications:

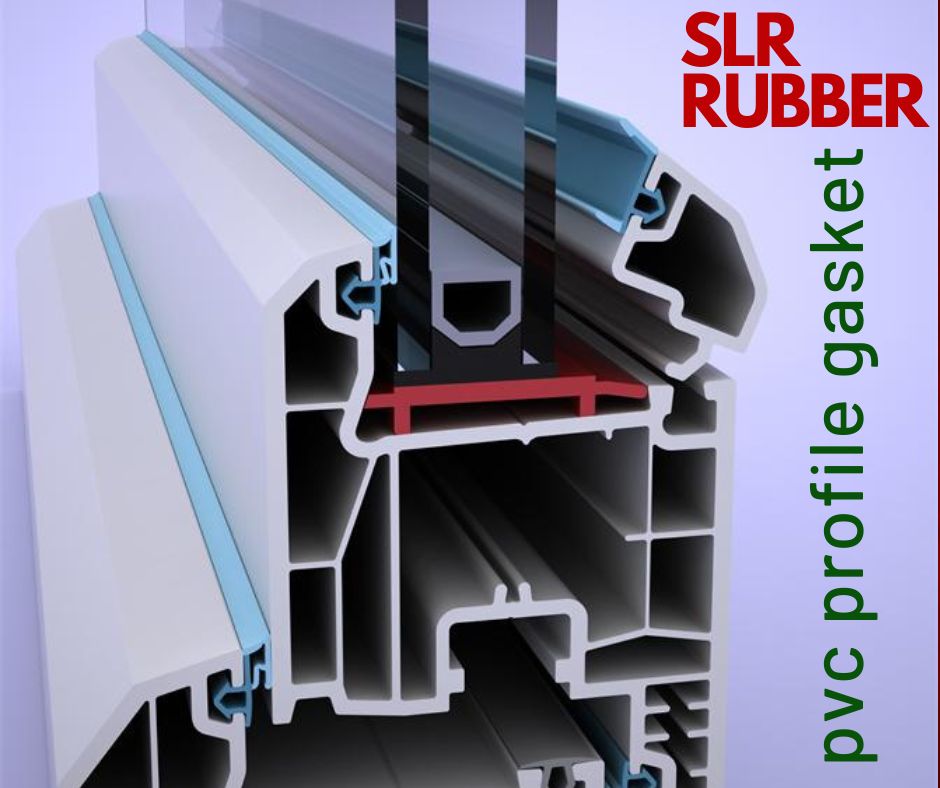

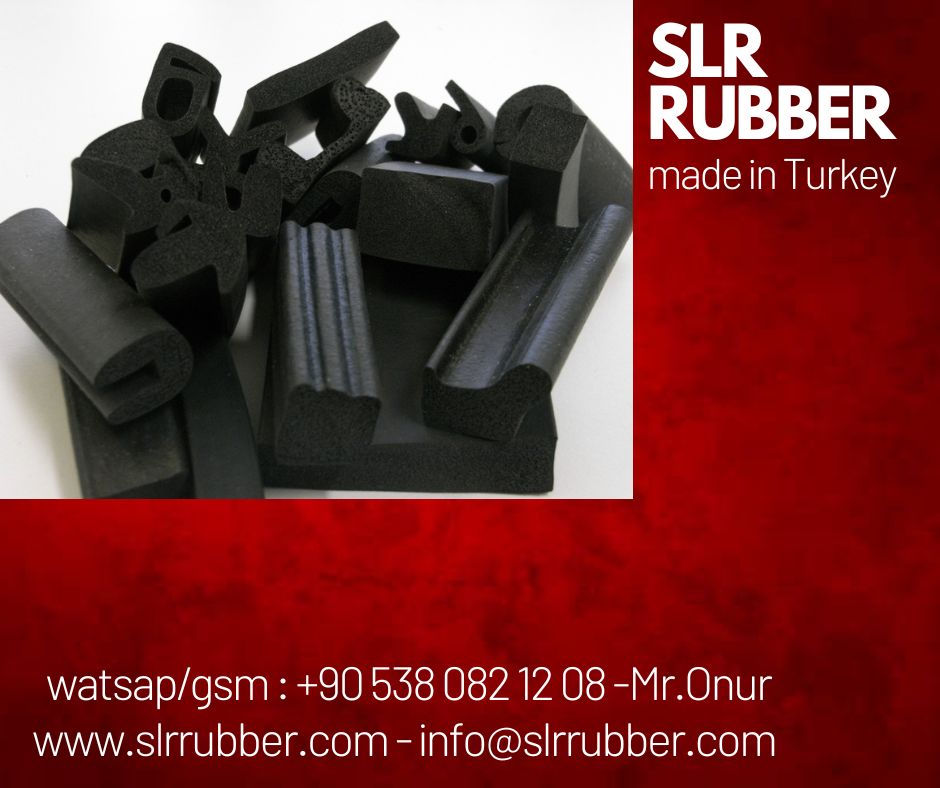

- EPDM rubber seals and gaskets find applications in a wide range of industries, including automotive, construction, HVAC, plumbing, and electrical. Common uses include door seals, window seals, O-rings, gaskets, hoses, and roofing materials.

-

Manufacturing Standards:

- EPDM rubber seals and gaskets are often manufactured in compliance with industry standards to ensure consistent quality and performance.

-

Customization:

- Manufacturers can produce EPDM seals and gaskets in various shapes and sizes to meet specific customer requirements.

-

Cost-Effective Solution:

- EPDM rubber is often chosen for its cost-effectiveness and long service life, making it a preferred material in many industrial applications.

When selecting EPDM rubber seals and gaskets in the USA, it's essential to consider the specific requirements of the application and ensure that the products meet industry standards and regulations.